ABOUT HYDRO-ABRASIVE CUTTING

A water jet mixed with garnet abrasive is used to cut through various materials including steel, refractory, concrete, epoxy, grouts and combinations of these.

Our first hydro-abrasive cutting project was in 1978.

High-pressure pump units are diesel engine driven. These start from the smallest unit at 125kW. We also have one @ 160kW electric VFD unit.

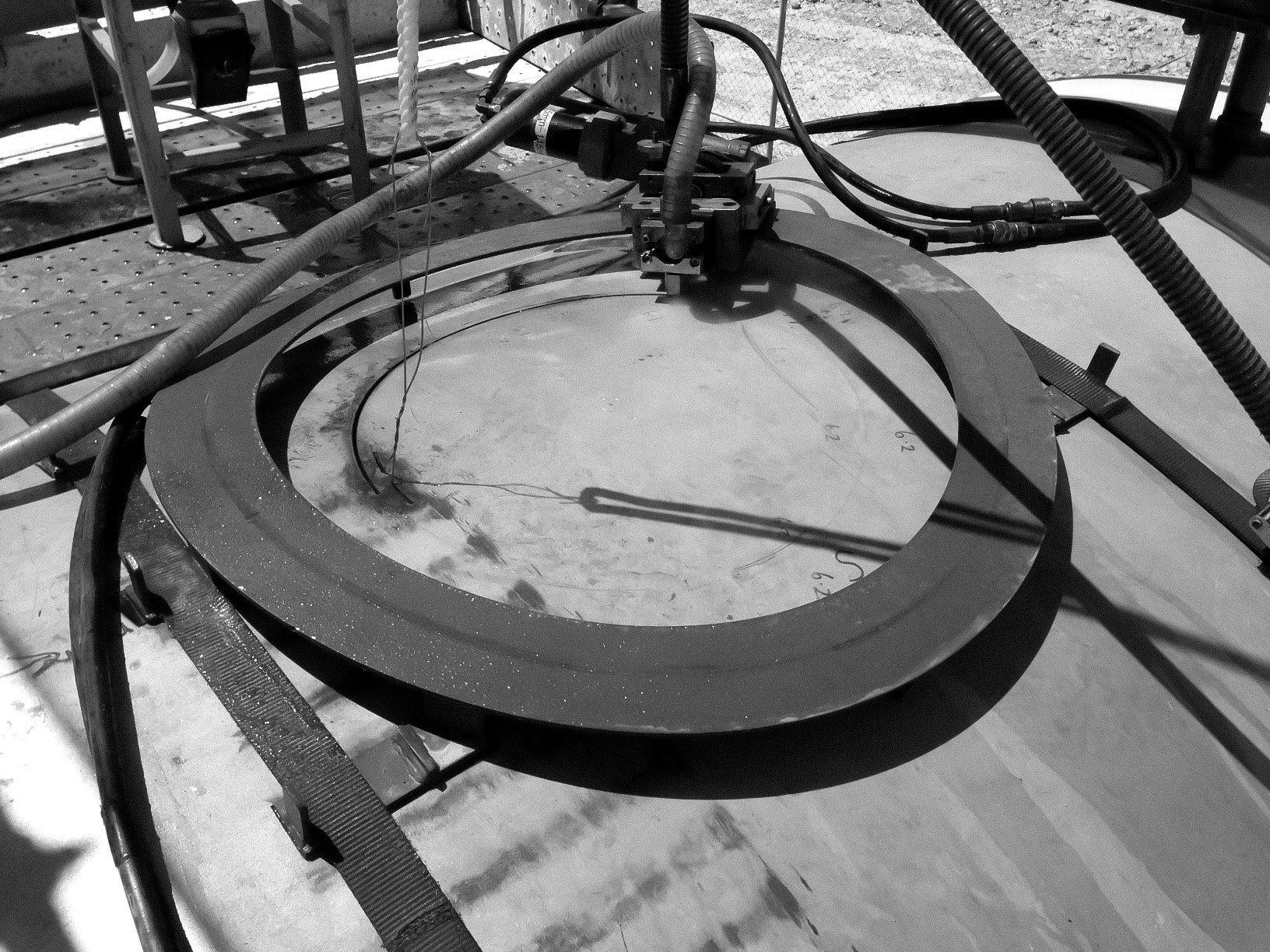

We use our own exclusive drive and tracking systems for controlled traverse rate, direction, angle and stand-off. These have proven to be reliable, safe and efficient for decades.

Our super-compact nozzle and tracking system allows cuts to be made in restricted spaces. The cutting head needs as little as 155mm of clearance.

Steel is hydro-abrasively cut to produce a weld preparation finish at the required angle.

The finish of the cut ensures that no re-work is required to create the weld preparation.

For refractory-lined pipes and vessels, the water jet cuts through the steel, refractory and reinforcing all at once – the steel shell does not have to be stripped of the refractory first.

Access doors are cut with such quality and precision, the sheet removed can be reinstated once work is complete. This avoids the manufacture of a new door.

Our 3-dimensional tracking system can cut door sheets of various shapes, in conical and cylindrical vessels. The quality of the cut ensures that the door sheet can be reinstated, once maintenance work is completed.